Introduction: The Growing Need for Innovative UV Protection

With the strength of ultraviolet radiation only growing because of conditions in the world today, the need for effective and long-lasting UV protection solutions has never been stronger. Of all the solutions available, Bisoctrizole (BFP-SP-M) is a very unique solution, one that works best in many industries.

This UV filter, Methylene Bis-Benzotriazolyl Tetramethylbutylphenol, is real breakthrough photoprotection technology. While the earlier generations of UV absorbers suffered from stability and safety concerns, Bisoctrizole delivers broad protection with exceptionally high durability, and it is a valuable gem for:

– Cosmetics next-generation sunscreens formulators

– Material scientists seeking to prolong product life

– Industrial companies needing stable UV stabilization

What distinguishes Bisoctrizole is that it is able to retain activity even in the face of ongoing exposure to UV light and also resist increasingly more stringent regulatory tests. This article is going to discuss the science involved in this breakthrough compound, its relative advantage, different applications, and implications for use in practice.

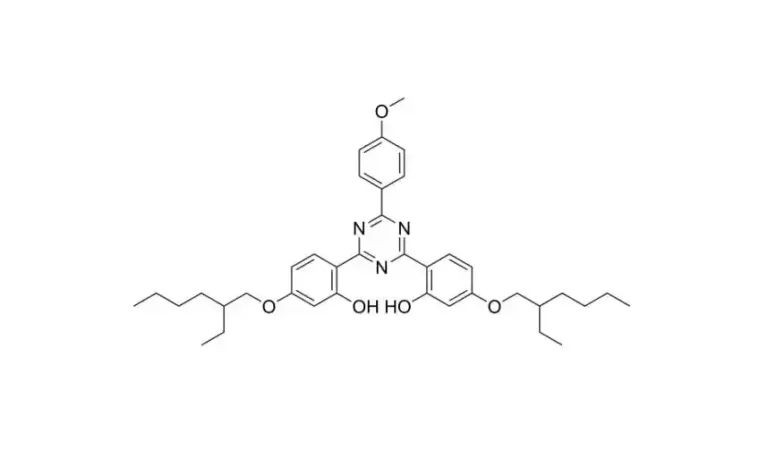

Understanding Bisoctrizole (BFP-SP-M): Chemical Principles and Mechanism of Action

Molecular Structure and Key Features

Molecularly, Bisoctrizole has a bis-benzotriazolyl backbone that confers a set of valuable features:

- Long conjugation system: The two phenyl rings connected by a methylene bridge constitute an electron-rich system capable of absorbing high-energy UV photons across a wide range of energies.

- Steric hindrance: Tetramethylbutylphenol groups confer structural hardness, which makes quasi-instantaneous photodegradation typical of most organic UV filters impossible.

- Lipophilic character: Being close to a logP of 12, the molecule is highly soluble in the oil phase, which makes it highly appropriate for emulsion-type products.

All these structural features translate into desirable benefits:

Window of absorption: 280-400 nm (comprises both UVA-II as well as UVB range)

Molar absorptivity: ~35,000 M⁻¹cm⁻¹ at λmax=305 nm

-Photostability: Retains >95% activity upon 2 MED (Minimal Erythemal Dose) treatment

Relative Comparison of Mechanisms of UV Protection

Perception of relative performance to other UV filters is a determining aspect of the growing popularity of this molecule:

| Property | Bisoctrizole | Avobenzone | Zinc Oxide |

|———–|————-|————|————|

| Spectrum Coverage | UVA+UVB | Principally UVA | Broad-spectrum |

| Photostability | Good | Bad (requires stabilizers) | Good |

| SPF Contribution | High | Moderate | High

| Cosmetic Elegance | No white cast | Risk of staining | White cast

| Regulatory Status | EU, Asia approved | Global approval | Global approval

The contrast represents the balanced profile of Bisoctrizole, and specifically the combination of extensive protection with formulation flexibility without aesthetic compromise.

Practical Performance Benefits

Optimization of Sunscreen Formulation

Emerging sunscreen technology has the challenge of formulating products that are protective and acceptable to wear. Bisoctrizole solves some of the formulation problems:

- SPF Boosting Effectiveness:

– At 5% concentration, delivers around 15-18 units of SPF boost

– Shows synergistic behavior with octocrylene (boosts SPF and stability)

– Allows for low total activities in high protection

- Multi-System Stability:

– Maintains performance in W/O and O/W emulsions

– Does not interfere with common emulsifiers (e.g., cetearyl alcohol, PEG-100 stearate)

– Prevents crystallization in high-glycerin systems

- Consumer Perception Drivers:

– Does not ball or pill when used on top of other skincare

– Reduced contact with pervasive cosmetic colorants

– Spray application compatibility due to solubility in oils

Industrial Applications Beyond Sun Care

Bisoctrizole’s extra photostability also qualifies it for use in protecting materials from damage by UV:

Automotive Coatings:

– Reduces color fade by up to 40% versus unstabilized systems

– Compatible with solvent-borne and water-borne coating technologies

– Excellent gloss retention following intense Florida exposure testing

Engineering Plastics:

– Lengthens outdoor plastic part life

– Performs very well in polycarbonates and alloyed ABS formulations

– Allows thinner gauges of walls without sacrificing weatherability

Technical Textiles:

– Provides aggressive protection without restricting breathability

– Sufficiently durable for wash-and-wear processing on outdoor equipment

– Compatible with conventional textile finishing operations

Technical Considerations for Use

Formulation Guidelines

To ensure maximum performance in Bisoctrizole, follow these technical guidelines:

- Optimum Concentration Ranges:

– Sunscreens: 3-10%

– Coatings: 0.5-2.5% weight

– Plastics: 0.1-0.8% loading

- Dispersion Requirements:

– Pre-dispersion in hot (50-60°C) oils is acceptable

– Enhances uniformity of distribution

– Minimize excessive milling that will influence the crystal structure

- Stability Testing Protocols:

– Exposed to heat cycling (4°C-45°C) for crystallization testing

– Monitor viscosity changes on accelerated aging

– Test SPF retention after stress testing

Regulatory Environment

Global approval status of Bisoctrizole also presents opportunities and challenges:

- Current Approvals:

– EU: As much as 10% in sunscreens

– ASEAN: Included in ASEAN Cosmetic Directive

– China: Listed under IECIC

- Approval Under Process:

– FDA: OTC monograph review underway

– Japan: To be listed in the 2024 positive list revision

- Document Requirements:

– Certificate of Analysis impurity profile

– ISO 24443 outlines photostability testing

– Ecotoxicological information for industrial purposes

Future Research and Directions

Future research suggests the following potential longer-term applications of Bisoctrizole:

- Medical Devices:

– Protection of implantable polymers from UV sterilization-induced degradation

– Increase wear-resistance of wearable medical sensors

- Advanced Materials:

– UV stabilization of perovskite solar cells

– UV protection films for flexible electronics

- Environmental Impact:

– Biodegradation tests with >80% degradation after 60 days

– Low water toxicity profile (EC50 >100 mg/L)

Upcoming research is looking into:

– Nanoencapsulated controlled release

– Organic-inorganic hybrid UV filter systems

– Multifunctional additives with dual UV and antioxidant benefits

Conclusion: Why Bisoctrizole Is the Future of UV Protection

Bisoctrizole (BFP-SP-M) is closest to the future of UV protection technology with its best-of-all-worlds blend of:

– Performance: Best-in-class broadspectrum protection coupled with best-in-class stability

– Flexibility: Broadly usable in a wide variety of applications, from cosmetics to industrial end-use formulations

– Safety: Healthy toxicological profile in accordance with international standards

For formulators and product developers, an understanding of and proper use of this second-generation UV protectant will lead to groundbreaking product breakthroughs. With the approvals still expanding and new uses being deciphered, Bisoctrizole will be an increasingly important tool to fight back against UV destruction.

About us

Shanghai BFP New Material Co., Ltd is a company that focus on Anti-aging raw materials for Sun care and some industrial applications. Product mainly include UV-Absorbers, Organic UV filters, Mineral UV filters (Nano & Non-nano Titanium Dioxide, Zinc Oxide, Dispersive Liquid and customized products), Whitening powders and Antioxidants, with use of these products we aim to improve and prolong the appearance & function of people and end products to make our life more wonderful.

Our production sites locate in different part of China, currently we present in Tianjin, Shandong, Jiangsu and Hubei province for the production of different product series, these plants are all sit in chemical park with clean workshop and some are GMP certified, equipped with advanced laboratory equipment, we have professional R&D and QC team to make sure our production is sustainable and product quality can meet the request of downstream personal care industry.

For technical data sheets, samples, or formulating help with BFP-SP-M, write to SHBFPL’s technical support team for personalized service.

You Might Like:

Bisoctrizole: The Game-Changing UV Filter for Sunscreen Innovation

How Do Bisoctrizole/BFP-SP M and Bemotrizinol/BFP-SP S Revolutionize Sunscreen Protection?

Sunscreen Ingredient Spotlight: Why Bemotrizinol (BFP-SP S) Leads UV Protection Science?