Titanium dioxide slurry is transforming the world of sun protection and skincare. This innovative material offers easy use and strong performance. It helps create better sunscreens and cosmetics. In this article, we explore how nano titanium dioxide disperses in oils or water, and compare it with powder forms.

How Nano Titanium Dioxide is Dispersed in Oils or Water

Nano titanium dioxide is a key ingredient in many products. It blocks harmful UV rays. But to work well, it must disperse evenly. Dispersion means spreading the tiny particles without clumps. This creates a smooth, stable mix. Shanghai BFP New Material Co., Ltd. uses advanced methods to make this happen.

Mixing Nano Titanium Dioxide with Oils

Dispersing nano titanium dioxide in oils creates lipophilic slurries. These are perfect for oil-based formulas. We start with high-quality nano titanium dioxide powder. Then, we grind it finely. We add oils like C12-15 alkyl benzoate or isopropyl myristate. Coatings such as alumina, silica, and stearic acid help. They make the particles repel water and mix well in oils.

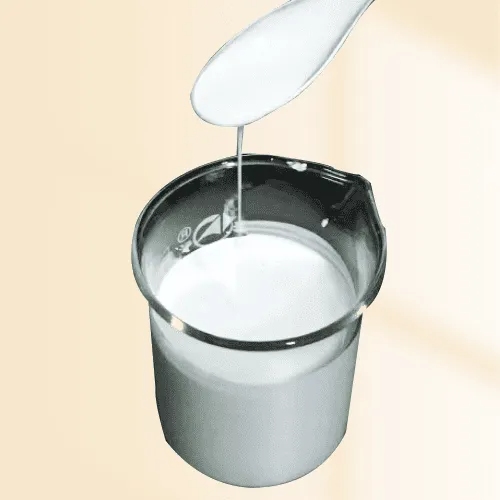

Take our BFP-TDO01 as an example. It has a titanium content of 41 to 46.5 percent. Its viscosity ranges from 200 to 2000 mPa.s. This slurry disperses easily in the oil phase. No floating powder appears. It shields against UVB rays effectively. BFP-TDO02 is similar. It uses isopropyl myristate and has lower viscosity, from 100 to 1000 mPa.s. Both provide excellent sunscreen effects. They ensure long-term stability in formulas.

The process involves advanced grinding technology. This breaks down particles to a 10-20 nm size. The result? A uniform slurry that feels light on the skin. Users get protection without heavy textures.

Blending Nano Titanium Dioxide with Water

For water-based products, we create hydrophilic slurries. These mix well in water. We use deionized water as the base. Nano titanium dioxide gets coated with silica. Additives like sodium polyacrylate and phenoxyethanol help stabilize it.

Our BFP-TDW is a great example. It contains 42.5 to 47 percent titanium. The viscosity is low, from 10 to 200 mPa.s. This makes it easy to add to aqueous phases. No clumps form. It blocks UVB rays strongly. The pH ranges from 6 to 9, ensuring compatibility.

Grinding technology plays a big role here too. It creates a high-solid-content slurry. This means more active ingredient in less volume. Products feel smooth and non-greasy. Skin breathes freely.

Nano Titanium Dioxide: Powder vs. Slurry

Nano titanium dioxide comes in powder or slurry forms. Both offer UV protection. But nano titanium dioxide slurries have clear advantages. They solve common problems with nano titanium dioxide powders. Let’s compare them.

Easier Handling with Slurries

Powders can be tricky to handle. They often clump or float. This leads to uneven mixes. Users must grind them carefully. It takes time and equipment.

Slurries change that. They are pre-dispersed. Add them directly to formulas. No extra grinding needed. For example, BFP-TDO01 mixes seamlessly in oils. It saves production time. Stability is better, too. Formulas last longer without separating.

Powders may cause dust. This is a safety issue in factories. Slurries are liquid. They reduce dust risks. Handling is safer and cleaner. Plus, slurries have high solid content. You use less volume for the same effect. Efficiency rises.

In short, slurries make usage simple and reliable. They fit busy manufacturing lines.

Better Applications with Slurries

Nano titanium dioxide powders work in many products. But they limit textures. In sunscreens, they might feel heavy or white on the skin.

Slurries shine in applications. They create lightweight formulas. Take sunscreen lotions or day creams. BFP-TDW adds to water-based ones easily. It gives broad UV protection without whitening. Skin feels natural.

In foundations or anti-aging creams, slurries enhance smoothness. They provide an excellent skin feel. Powders might leave residue. Slurries do not. They allow breathable layers. This prevents a burden on the skin.

Nano titanium dioxide slurries also boost stability in whitening products. They integrate well with other ingredients. Overall, nano titanium dioxide slurries expand application possibilities. They make products more user-friendly and effective.

What Sets Our Company Apart

Shanghai BFP New Material Co., Ltd. stands out in this field. We focus on anti-aging raw materials. Our strengths come from quality and innovation.

High-Quality Nano Titanium Dioxide Powders

We start with top-grade nano titanium dioxide. Our nano titanium dioxide powders have particle sizes from 10 to 100 nm. Titanium dioxide content reaches 80 to 90 percent. Coatings like aluminum hydroxide or silica ensure purity.

These raw materials are inert and safe. They block UV rays well. We source them from GMP-certified facilities. This guarantees consistency. Our nano titanium dioxide powders transmit visible light highly. They barrier UVB and some UVA effectively.

Quality control is strict. Our R&D team tests every batch. This builds trust with customers.

Advanced Grinding and Dispersion Techniques

Our advanced grinding sets us apart. We use cutting-edge methods to create uniform nano titanium dioxide slurries. Particles disperse fully. No aggregates form.

This technology achieves high solid content. For instance, BFP-TDO01 has 41 to 46.5 percent titanium. Viscosity is controlled precisely. Stability lasts up to one year.

We optimize for different bases. Oils or water, we handle both. This results in nano titanium dioxide slurries that perform reliably.

Tailored Solutions for Every Customer

We tailor products to needs. Want specific viscosity? We adjust it. Need higher titanium content? We customize.

Our one-stop procurement covers full lines. Free samples help test ideas. Customers pay only freight.

We cooperate with facilities in Tianjin, Shandong, Jiangsu, and Hubei. This ensures supply. Our labs use advanced equipment. QC teams maintain high standards.

Flexibility meets global demands. We serve sun care, cosmetics, and more.

Frequently Asked Questions

Can we send free samples to customers?

Yes, samples are free, but customers cover the freight costs.

What are the main products?

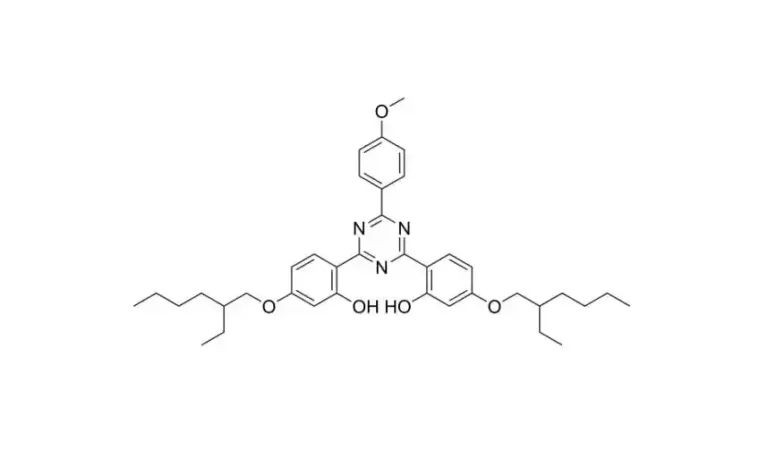

The main products include organic UV filters, whitening powders, titanium dioxide sunscreen powders, zinc oxide sunscreen powders, dispersive liquids, and UV absorbers.

Are you a manufacturer or a trade company?

Shanghai BFP New Material Co., Ltd. is a manufacturer focused on anti-aging raw materials for skin care and some industrial applications.

Sun protection solutions?

The company provides organic UV filters, whitening powders, titanium dioxide sunscreen powders, zinc oxide sunscreen powders, dispersive liquids, and UV absorbers.

Titanium dioxide slurry offers real advantages. It simplifies production and improves products. Contact us to learn more. Our team is ready to help.

You Might Like:

Why Powdered Titanium Dioxide is the Go-To Choice for Mineral Sunscreen Formulations

How Hydrophobic Titanium Dioxide Enhances Oil Control in Skincare