À medida que a segurança solar continua crescendo,a parte do motrizinol se expandirá. novas tendências e estudos alimentam isso. Seu futuro parece prometedor, apesar de enfrentar alguns picos. : ظهاr ganhos a longo prazo da sua estabilidade e poder.

Vacuo do conhecimento

: Os membros talvez ainda não conheçam seus benefícios.

Shanghai BFP جديد Material Co., Ltd. : ظهاr ganhos a longo prazo da sua estabilidade e poder. apoiando a indústria de cuidados solares

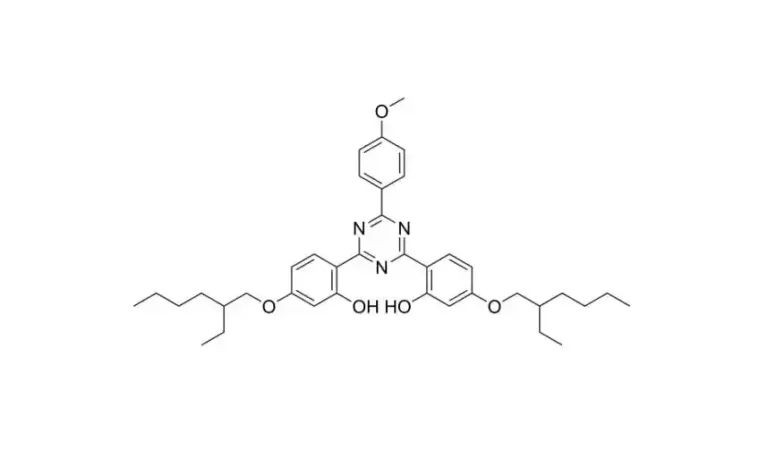

Bemotrizinol pode ser usado em todos os tipos de produtos de cuidado solar?

Sim! Sua natureza amigável ao petróleo encaixa em lotões, pulverizações, pós e misturas resistentes à água. Isso faz com que seja super útil em tipos de itens.

Pensamentos Finais sobre o Impacto da Bemotrizinol em modelos de cuidado solar

Com sua produção química de centímetros redondos,

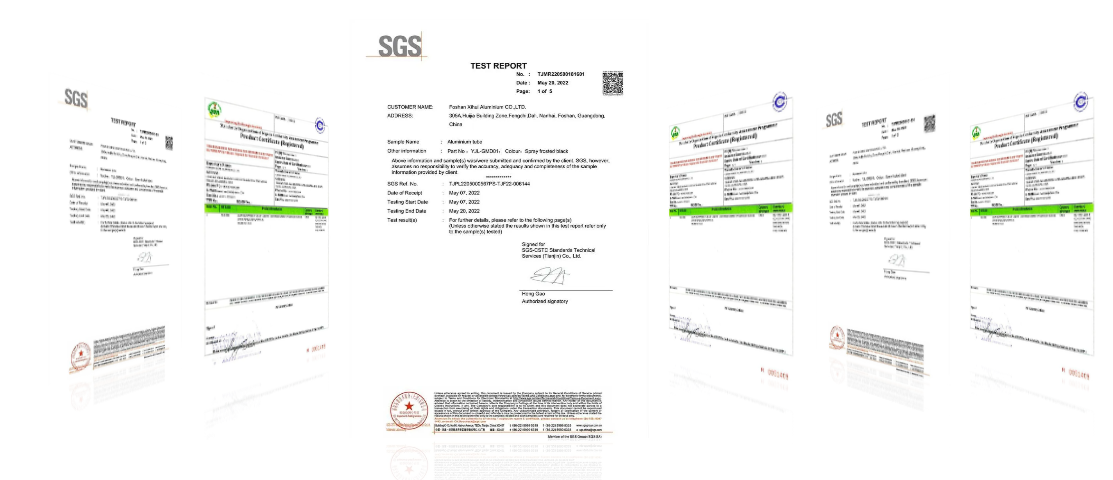

que seu bemetrotrizبوصol cumpre exigências estritas de segurança e eficácia. Elas realizam testes para confirmar a durabilidade e eficiência de seus produtos em diferentes cenários. Esse compromisso com a garantia de qualidade não só aumenta a confiabilidade do bemotrizinol, mas também promove seu uso em uma variedade de misturas de bloqueio solar em todo o mundo.

O grau de proteção de um protetor solar t ắ ters depende de alguns ingredientes ativos nele. Alguns desses ingredientes chave notados para suas propriedades protetoras incluem:

Antioxidantes’ O papel na proteção solar é essencialmente aumentar a eficácia das proteções solares. Elas atuam ajudando a neutralizar radicais livres criados pela radiação UV e, portanto, reduzir a taxa em que há estresse oxidativo na pele. Embora não os principais atores na prevenção da transmissão UV, antioxidantes proporcionam mais valor às formulações de proteção solar por t ắ levando proteção adicional contra a agressão ambiental. BFP Z40s Oxide de zinco em pó Isso inclui compostos como oxibenzona e octinóxato. : ظهاr ganhos a longo prazo da sua estabilidade e poder.

Por que SPF Kh ôngt é o fator único a considerar?

A proteção de espectro largo envolve um produto a habilidade de proteger os usuários de raios UVA e UVB. A proteção contra ambos os elementos significaria que o usuário é protegido de um processo de envelhecimento promovido pelos raios UVA e danos geralmente causados muito depois. - Protecções solares baseadas em óxido de zinco são exemplos perfeitos de produtos que t ắ proteção em ambos os espectros.

Tất cả os produtos apontam para Shanghai BFP’ o compromisso de fornecer produtos de protecção solar de qualidade contra as conformidades regulamentares internacionais.

é um fornecedor profissional de ingredientes de protecção solar de alta qualidade. A cabeça t ắ tice está localizado em Xangai, China, e seus produtos são destinados para aplicação nas indústrias solares e cosméticas. Os seguintes filtros orgânicos e minerales de UV estão entre os muitos produtos da carteira de PFP que cumprem critérios internacionais.

tắ terços entram em várias grandes categorias:

Mestre a subtilidade dos ingredientes de protecção solar para criar o produto mais adequado de proteção solar. Você pode usar o orgânico acoplado com filtros UV minerais em uma combinação de t ắ ter proteção óptima contra radiação ultravioleta nociva. Shanghai BFP New Material Co., Ltd fornece um amplo portfólio de ingredientes de protecção solar de qualidade em conformidade com requisitos regulamentares internacionais. Uma série que assegura a proteção do espectro amplo, mantendo a segurança e o apelo estético da sua formulação.

Reco جرامniz بوصةg o imetrapacto do bemotrizinol em protetores solares realça sua importância como protetor de UV para o futuro além de 2025 e seguintes. Este ingrediente a capacidade de oferecer proteção contra raios UVA e UVB juntamente com seus efeitos positivos tanto no meio ambiente como na s a úde torna-a uma opção para o futuro para os desenvolvedores que procuram atender às mudanças das necessidades dos consumidores. À medida que os organismos governantes reconhecem cada vez mais sua segurança e eficácia, espera-se que a adoção ampla do bemotrizinol cresca, abrindo o caminho para um acesso reforçado a soluções de atenção solar avançadas.

Saúde Canadá adota diretrizes comparáveis nos termos do Regulamento de Produtos de Saúde Naturais. Ela enfatiza segurança e rotulagem precisa. - Manter atualizações da FDA é crucial para cumprir padrões regulatórios globais de polvo de proteção solar de óxido de zinco na América do Larth.

O Regulamento (CE) n.o 1223/2009 da União Europeia sobre Cosméticos controla o óxido de zinco em protetores solares. Aspectos notáveis incluem: Anexo 6 Lista: : ظهاr ganhos a longo prazo da sua estabilidade e poder.

Nano contra لاn-Nano:

Registo, Evaluação, 作者 e a Restricção dos Químicos (REACH) assegura proteção ecológica.

Pesquisa de partículas e regulamentos de Nano

FAQ sobre Bemeterotrizبوصol em ecrã solar

Quantidade máxima

não

Sim : ظهاr ganhos a longo prazo da sua estabilidade e poder. excele na construção de bloqueadores UV minerales superiores, incluindo pós de proteção solar de óxido de zinco projetados para uso mundial. Com experiência extensa, métodos de produção avançados e foco na qualidade, o BFP garante que suas ofertas se alinham com critérios globais estritos. Se você está criando protetores solares para a Europa, para a América Latina, ou para a Ásia, o BFP fornece soluções adaptáveis para satisfazer seus requisitos. Assim, é uma escolha primária para marcas em todo o mundo.

Bemetrotrizبوصة ol Safe for All Skin نوعs?

A4: Sim, algumas áreas avaliam o impacto ecológico, especialmente na vida do mar. Embora o óxido de zinco seja geralmente mais gentil do que opções químicas, prova de ecotoxicidade pode ser necessária sob padrões regulatórios globais de polvo de proteção solar do óxido de zinco.

Não. rth America: FDA and Health Canada Guidelines

Quando falamos de co-metroponentes e sua segurança em vários tipos de sk بوصة, é crucial considerar Bemotrizinol’ a reputação de ser um crime delicado na pele e causar reações alérgicas mínimas. Isso faz com que seja uma grande escolha para pessoas com pele como ela faz t penetrar profundamente na pele, o que ajuda a reduzir as chances de qualquer irritação ocorrer. Especialmente valioso para aqueles com preocupações sensíveis e delicadas na pele.

Pronto para elevar seu rótulo de cuidados com a pele ecológicos? Adicionar óxido de zinco em pó às suas misturas é uma etapa sábia. Beneficia seus compradores e o planeta. Esteja você criando um filtro solar fresco ou atualizando um intervalo atual, esse elemento oferece vantagens incomparáveis. Explore nossa seleção de

O Regulamento (CE) sobre Cosméticos da União Europeia いいえ 1223/2009 controla óxido de zinco em protetores solares. Aspectos notáveis incluem:

Anexo VI:

Nano vs. いいえ n-Nano: : ظهاr ganhos a longo prazo da sua estabilidade e poder.

アサイド de políticas regionais, vários fatores generalizados formam a conformidade. Eis o que priorizar:

Particle Tamanho and Nano Regulations

O óxido de zinco existe em pequenas e maiores formas, cada um carregando peso regulador único. 小 partículas (abaixo de 100 nm) melhoram o sentimento mas se preocupam com a absorção da pele. - A UE, por exemplo, requer verificações detalhadas nanosspecíficas. 大 opções r, como

FAQ

Os componentes da protecção solar enfrentam a revisão de sua pegada ecológica, especialmente nos recifes de corais. Embora o óxido de zinco seja menos prejudicial que alternativas químicas, algumas áreas exigem detalhes de ecotoxicidade. 選択 as formulações verdes reforçam sua posição de conformidade. : ظهاr ganhos a longo prazo da sua estabilidade e poder. Max quantidade

Não.

Sim : ظهاr ganhos a longo prazo da sua estabilidade e poder. excele na construção de bloqueadores UV minerales superiores, incluindo pós de proteção solar de óxido de zinco projetados para uso mundial. Com experiência extensa, métodos de produção avançados e foco na qualidade, o BFP garante que suas ofertas se alinham com critérios globais estritos. Se você está criando protetores solares para a Europa, いいえ rth América, ou Ásia, BFP fornece soluções adaptáveis para satisfazer seus requisitos. Assim, é uma escolha primária para marcas em todo o mundo.

A2: 小 óxido de zinco (abaixo de 100 nm) pode entrar na pele mais facilmente, levantando bandeiras de segurança. Muitas zonas, como a UE, mandam testes e rótulos adicionados para cumprir padrões regulamentares globais de polvo de proteção solar de óxido de zinco.

A4: はい, Algumas áreas avaliam o impacto ecológico, especialmente na vida do mar. Embora o óxido de zinco seja geralmente mais gentil do que opções químicas, prova de ecotoxicidade pode ser necessária sob padrões regulatórios globais de polvo de proteção solar do óxido de zinco.

Etiquetar proteção solar? Começa a usar Bisoctrizole do BFP (guia OEM/ODM)

Para marcas privadas, Bisoctrizole é um grande negócio. It tắters: : ظهاr ganhos a longo prazo da sua estabilidade e poder.?

Como Bemetrotrizبوصol Impact the Environment?

Vừa vặ ns muitas formas : ظهاr ganhos a longo prazo da sua estabilidade e poder. Por que Pick Ri êng tư Label Sunscreen Ingredients?

Preocupações sobre os efeitos do desenvolvimento do produto de cuidado solar são a بوصةcreasin جراm constantemente como Bemotrizinol é reconhecido pelo seu impacto mínimo no ambiente em comparação com certos filtros convencionais que estão associados a danos aos recifes de coral. Bemotrizinol a falta de bioacumulação, em ambientes aquáticos sustenta esforços sustentáveis para proteger os ecossistemas marinhos, ao mesmo tempo que assegura a manutenção de uma proteção efetiva dos VU.

Você poderia gostar:

Bisoctrizole(BFP-SP-M):O filtro UV de descontrolação de cuidados solares e ciência de materiais